Finding a Manufacturer...navigating the challenges: The FORGETSPECS journey (Part 3)

If you’re just joining us this is Part 3 of the ForgetSPECS Journey, a blog series where I’m sharing my adventure to create the world’s first prescription screen protector. Read Part 1 to find out how how it all started and Part 2 I share how I discovered nanotechnology and how we are using it to create a prescription screen protector.

If you have been following the ForgetSPECS journey so far, you know that we have had an initial design and provisional patent for some time now.

We had been able to print samples of our design on a nanoscribe 3D printer so we knew our design worked – but the next step was to source a manufacturer who could build a full-scale prototype and manufacture at scale.

Surely this would be the easy part - it turns out that finding the right manufacturing wasn’t so easy after all!

What I quickly learnt was that our product was market-leading in design – but also in manufacturing capability. We had just designed a product that was too advanced for nanotechnology manufacturing in Australia.

That should be enough to stop any sensible person. Not me. I didn’t realise how persistent and resilient I was. Definitely not patient. Things weren’t happening quickly enough for me.

Due to the complexities of manufacturing, the international search began again…

In 2018, I recruited a prototyping expert who had advised screen protector companies in the past, and he knew someone in Japan that he thought would have the capabilities to produce our films.

After many video conferences with Japanese agents and much research we decided to go and meet some manufacturers in Tokyo. Both of us travelling for 7 days was quite an expense, but his agent re-assured us that it was the best strategy – being a mark of respect and good for relationship development. It was a great achievement to gain an audience with a multinational Japanese plastics manufacturer - a real “pinch me moment”.

After a lot of preparation and learning about cultural exchange, we were ready to meet the Business Development Manager – whose agent was our interpreter. The meeting began. Formal introductions were made and I had to wait my turn to talk. After about 15 minutes, we start to get to the nitty gritty – our film thickness, number of lenses, size of lenses, radius of curvature of lenses and the precision of manufacture. I explained we required lenses 59 microns in diameter, non-repeating pattern, each lens different.

STOP THERE!!!! What did you say?

Non-repeating design. A deal breaker.

They could only do a repeating design with the required precision. GAME OVER. The meeting ended.

Whilst we had overcome many challenges to do with planning, time and cost we were dead in the water after 15 minutes because a critical design component had not been discussed previously.

The search for a manufacturer continued….

I had flown to Los Angeles, Shanghai and Japan to meet with potential manufacturers. Some of these companies were manufacturing for Fortune 500 customers including NASA. Many were confident that they could manufacture to our requirements, however, to no avail.

Then I had a breakthrough with a company in Massachusetts.

A plastics manufacturing company that made lenses for Fortune 500 companies were willing to collaborate on the research and development required to make this ground-breaking technology and manufacturing processes work. They would project manage the production of moulds and coordinate with a Los Angeles manufacturer. What a saviour! We had lots of meetings over Skype with directors, design teams, and third-party mould and film manufacturers. Woohoo we were making progress!

In November 2019 (7 months later), we had received our prototypes and had our first user testing.

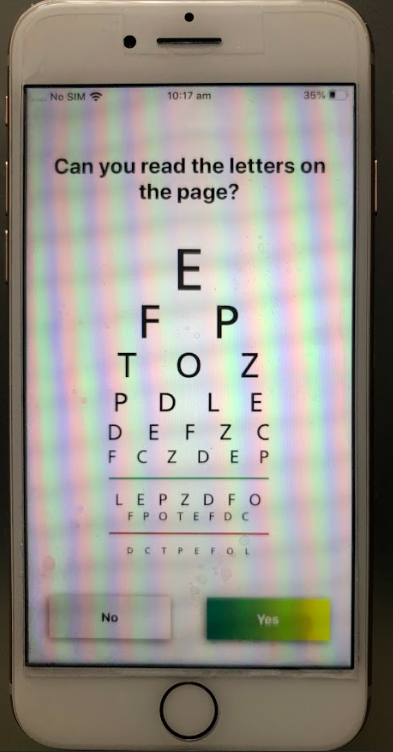

The moment of truth, I was sitting outside in a café on beautiful sun lit day, I applied the screen to the phone. OMG I could read it. I couldn’t believe my eyes. I was overcome with emotion and started to cry. My idea had come to fruition. The lens wasn’t quite perfect however - it had a rainbow effect across it that was distracting. But when you focused on the text, you could read it.

The next day, I sat in the board room with my first samples for iPhone 6/7/8. I asked Richard to take off his glasses and see if he could he read his phone. He said no – not without his glasses. I handed him my phone with a ForgetSPECS protector.

He said “yes I can, what have you done to it”?

I said “it’s not what I have done, it’s what you have done. That is the lens you manufactured”.

He was amazed. He just couldn’t believe his eyes.

That was the first independent customer reaction. We received incredible feedback following initial testing. One user, who would normally not be able to read his phone screen without eyeglasses, provided this feedback:

“My first impression of ForgetSPECS was shock! It was like reading my phone with my glasses on. I couldn't believe my eyes. My vision with the ForgetSPECS lens was so clear. Thankyou for sharing your product with me. I am still amazed!” - Richard

Just the validation we needed. So far it had been a journey with so many doubters, delays and knockbacks. Further testing told us that the screen was visible without glasses and the text could be read clearly.

We were now working with our Los Angeles manufacturing partner to work out how to produce the lenses at scale. They tested the process and in March 2020, we produced thousands of screen protectors in a 100ft continuous run.

The ‘rainbow effect’ remained. It was very distracting and didn’t provide our users with the seamless experience that we were aiming for. Rainbows are normally a beautiful phenomenon. Not this time!

What was the cause? How do we get rid of it? The project team couldn’t explain. We needed to identify the cause and find a solution for the rainbow.

Stay tuned for the next blog on the “Rainbow Connection”.